Fluoropolymers provide excellent chemical resistance. Partially fluorinated plastics, PVDF and ECTFE, offer excellent chemical resistance. Fully fluorinated plastics, FEP and PFA, are suitable for extreme conditions, up to 260 C°.

Fluoropolymers offer excellent chemical and temperature resistance for industrial piping and equipment. They are the right choice when the process contains strong acids, bases, or solvents and when safety and longevity must be assured.

Partially fluorinated plastics, PVDF and ECTFE, are excellently suited for applications where cleanliness and high chemical resistance are required. Fully fluorinated plastics, FEP and PFA, withstand almost all industrial chemicals and temperatures up to 260 °C.

Thanks to them, process equipment remains reliable for decades – without leaks or corrosion. Fluoropolymers are therefore an investment in the reliability of the production process. Their long service life and maintenance-free nature make them a sustainable solution in terms of total costs, when the goal is a safe and reliable production environment.

The best benefit from fluoropolymers is achieved only when the material is selected correctly according to the intended use.

PRP-Plastic has used fluoropolymers for over 30 years in demanding chemical piping and process solutions. We know the structures, limitations, and compatibilities of the materials. Thus we can ensure that the pipeline, lining, or component withstands the conditions of that specific process.

We supply only certified and tested components whose quality and safety have been verified.

Our experts support the customer throughout the entire project – from design to installation and the assessment of life-cycle costs.

The result is a solution that endures, saves, and makes process management easier.

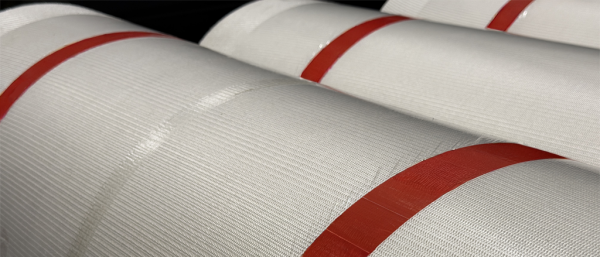

PVDF is a partially fluorinated plastic that combines chemical resistance and mechanical strength.

Especially suitable for clean processes and applications where tight, easily weldable structures are needed.

Operating temperature: –10 °C – +130 °C

Applications: chemical industry, water chemicals, cleanrooms

ECTFE expands the application range of fluoropolymers. It withstands low temperatures and strong chemicals better than PVDF.

An excellent option when long-term durability and corrosion protection are required.

Operating temperature: –40 °C – +140 °C

Applications: process piping, tanks, acid-resistant linings

FEP withstands almost all industrial chemicals, strong acids, and high temperatures.

Used especially in chemical piping and reactor linings where cleanliness and temperature resistance are required.

Operating temperature: –200 °C – +205 °C

Applications: chemical piping, tank linings, laboratory systems

PFA is the highest-performing material among fluoropolymers.

Its excellent resistance to chemicals and temperature makes it a perfect solution for extreme conditions – up to 260 °C.

Operating temperature: –200 °C – +260 °C

Applications: high-purity processes, chemical tanks, demanding industrial piping

RP is your choice when you want process equipment and piping to last year after year.