Gas scrubbers are often challenging in terms of chemical resistance, because the corrosiveness of many chemicals is accentuated in gaseous form. Our experts with extensive experience help already at the design stage to choose the right materials.

Gas scrubbers are constantly exposed to corrosive gases, acids, and moisture. The right material selection is a decisive factor so that the equipment withstands the chemical and temperature stresses caused by use.

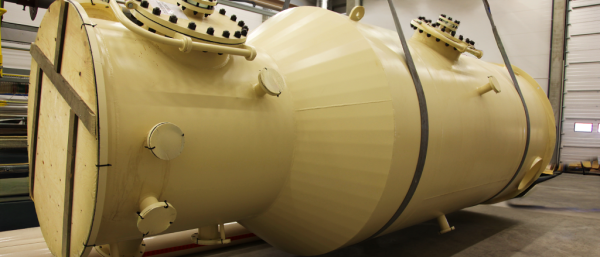

PRP’s gas scrubbers are manufactured from chemically resistant thermoplastics, fluoroplastics, or composite structures that guarantee long service life and maintenance-free operation. The solution is always selected according to the gas composition, temperature, and process – with safety and reliability first.

When materials and structures are chosen correctly, the gas scrubber withstands years of use without chemical wear or leaks.

PRP’s experts support the customer from design to commissioning, so that the process remains under control and production runs without interruption.

Over 30 years of experience in designing and manufacturing plastic process equipment makes us a reliable partner also in gas scrubbers.

We have implemented demanding solutions among others for the chemical, energy, and metal industries, where chemical resistance and process cleanliness are critical.

We supply:

All components are manufactured from certified materials, and structures are designed in accordance with standards to ensure safe and efficient use.

Contact us, and we will help to size and implement a gas scrubber solution that withstands the requirements of use and ensures a safe process.

RP is your choice when you want process equipment and piping to last year after year.