Fiber reinforced themorplastic pipes are excellent in applications that require resistance against corrosion, high temperature and pressure.

Our dual-laminate chemical pipes are light, do not require special maintenance and are easy to clean. The FRP surface giving the pipes mechanical strength also enable the use in higher temperatures and pressures.

We have good stock of dual-laminate pipes and flanges in PP/FRP, PE100/FRP, PVDF/FRP and PVC/FRP. Dual-laminate piping products also available with ECTFE, FEP and PFA thermoplastic as the chemical resistant layer.

Valves are also available in our range. We have plastic lined valves from Swissfluid and thermoplastic valves from FIP

The main applications are:

- chemical industry

- textile, paper and chemical pulp industry

- water treatment systems

- industrial pickling plants

- electrotype plants

- chlorine electrotype plants

- power plants

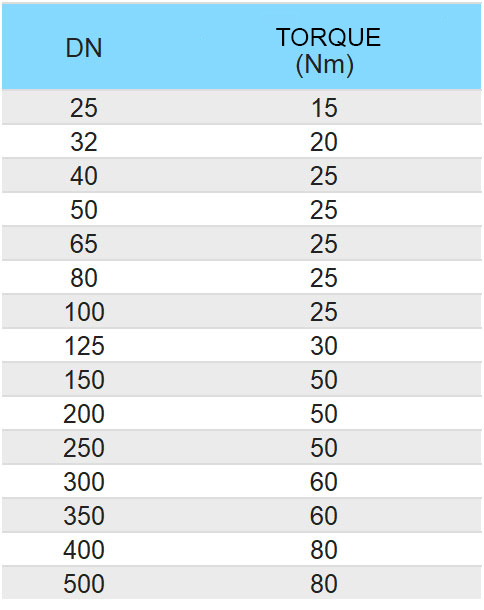

Torque

The bolts must be tightened steadily. It must be avoided to exceed the indicated torques. These torque of bolts are applicable to flange connections made of GRP by using flat gasket of elastomeres approx. 60°C.

Ask us

Is something left to bother you or do you possibly already want an offer for your work? Contact PRP-Plastic’s experts either via the contact form on the website, by email or by calling.

Jukka Niemimäki

Sales and production

Tel. +358 50 527 8457

jukka.niemimaki@prpplastic.fi

Jarkko Räihä

Managing Director

Tel. +358 40 777 0140

jarkko.raiha@prpplastic.fi